Factory source On Site Flange Facing Tools - IFF610 Portable Flange Facing Machine – Portable Tools

Factory source On Site Flange Facing Tools - IFF610 Portable Flange Facing Machine – Portable Tools Detail:

Detail

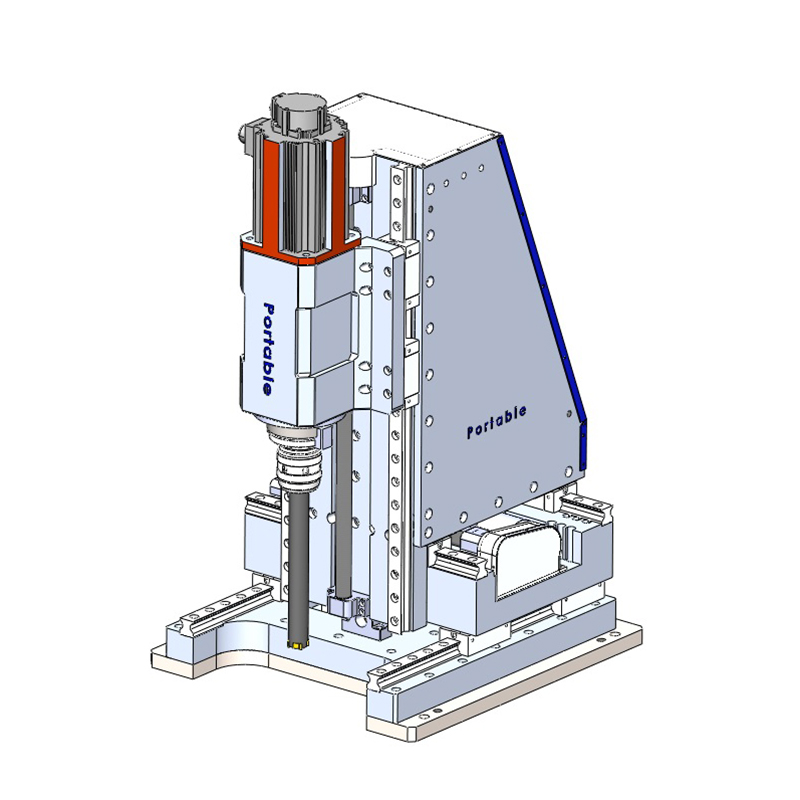

IFF610 Flange Facing is an overall cost effective technique which allows you to face, bevel,and turn pipe,value and pump flange with ease . Which in turn helps to keep your plant running efficiently, safely and more environmentally friendly.

It gives machine shop accuracy , combined with ease of handing and portability in the flange range .Spur gears engage directly on the drive ring, keep power requirements and losses to a minimum and allowing maximum torque at the cutting tool . When the machine is used in the vertical plane , balancing is greatly reduced.

IFF610 can be used in horizontally,vertically or overhead planes.

Application

IFF610 Portable flange facing machine application for Oil, Gas and Chemical ,Power Generation ,Heavy Equipment ,Ship building & repair.

Typical applications: Piping system flanges ,Valve flanges and bonnet flanges ,Heat exchanger flanges,Vessel flanges ,Flange faces on piping systems,Pump housing flanges, Weld preps,Tube sheet bundles, Bearing mounting bases,Final drive hubs,Bull gear faces.Manufacturing of mining equipment ,Slew rings ,Bearing mounting bases,Crane pedestal flange

Compact design

IFF610 portable flange facing machine, a compact tools for flange faces refacing. This robust and accurate on site flange facing machine cut a continuous groove spiral serrated finish. Machine the smooth finish, stock finish, RTJ grooves for ring type joint gaskets. It’s the essential on site flange facing tools to prevent gas leakage connection.

IFF610 flange facing machine working diameter: 50-610mm.

Function

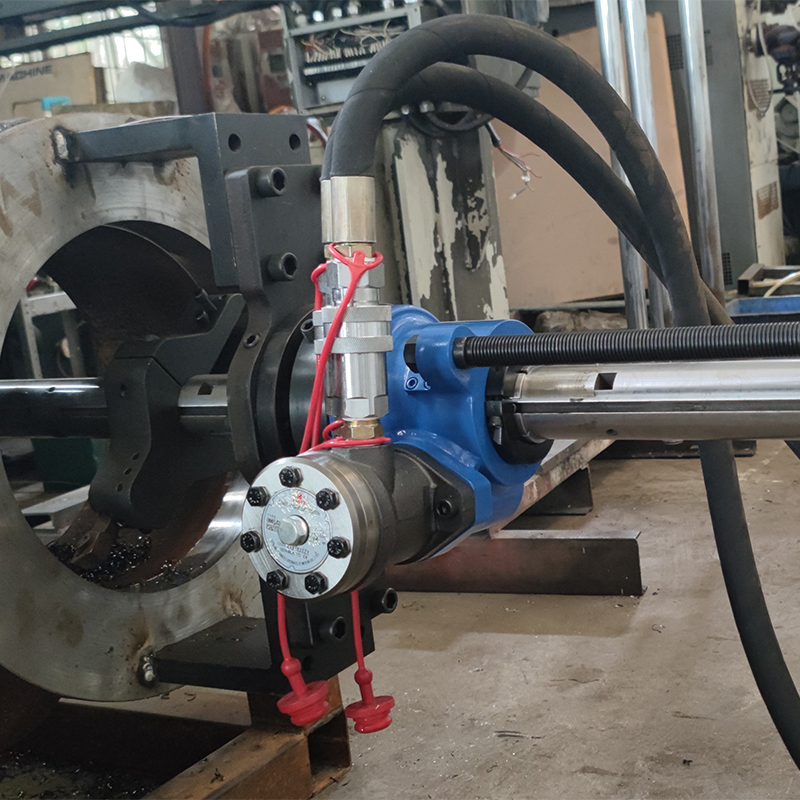

IFF610 resurface flat face and raised flange faces , it allows any technicians to produce RTJ grooves for ring type joint gaskets in minutes.

Geared continuous groove facing feeds for a gramophone finish

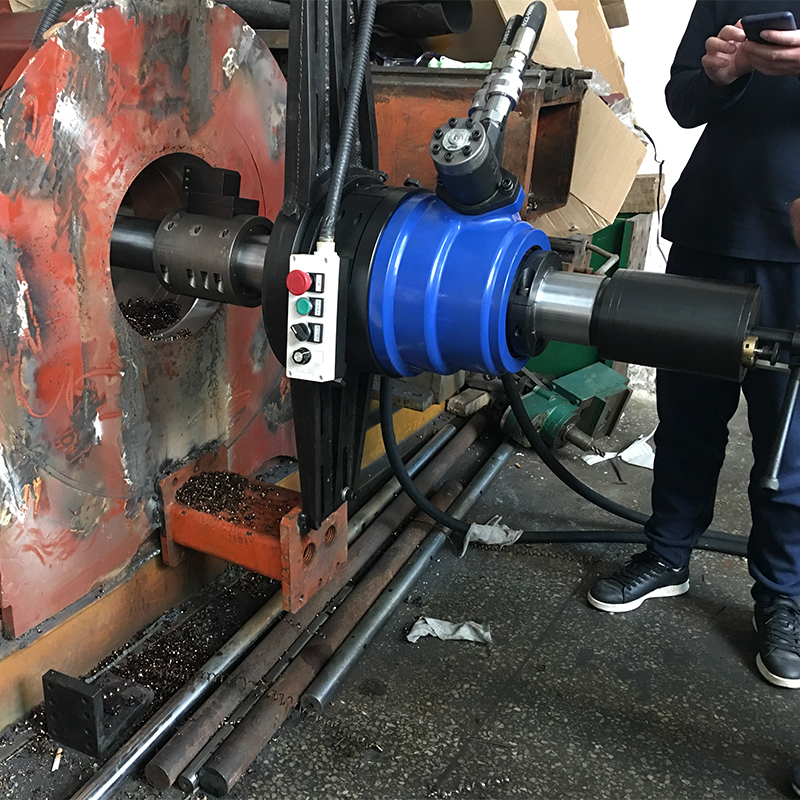

Drive Power

Portable flange facer IFF610 gets the powerful drive unit. No matter the electric motor, servo motor system or pneumatic motor, It has diversified power combinations to work with different on-site processing environments.

Lightweight

Body of machine weighs only 99 lbs (45 kg) Smallest mounting chuck weighs about 5 lbs (2.2 kg)

Simplified Operation

Single selector switch for bidirectional radial feed or vertical down feed One wrench size for clamping jaws and body draw bolt

Quick and Easy Setup & Removal

Separate mounting chuck

All centering and leveling is done on the chuck

IFF610 flange facing machine is supplied complete with toolkit including tools and inserts, air filter lubricator and hose connection, all required mounting base and extensions, storage / shipping box

Cost Effective

Mount the ID flange in seconds

Reduces downtime

Eliminates off-site machining costs

Cutting high precision phonographic finish of smooth and stock finish.

Eliminates leak sealing procedures

Reliable and rigid of machined materials

Reduces stock of replacement flange

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of Quality is the life of the company, and reputation is the soul of it for Factory source On Site Flange Facing Tools - IFF610 Portable Flange Facing Machine – Portable Tools , The product will supply to all over the world, such as: Uruguay, Anguilla, Swiss, We aspire to meet the demands of our customers globally. Our range of merchandise and services is continuously expanding to meet customers' requirements. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!