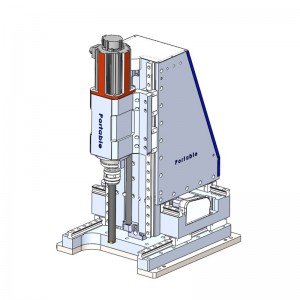

GMM3010 Gantry Milling Machine

Detail

| X axis | 3000mm |

| Y axis | 1000mm |

| Z axis | 150mm |

| X/Y feed | Auto feed |

| Z feed | Manually |

| X power | Electric motor |

| Y power | Electric motor |

| Milling head drive(Z) | Hydraulic power unit,18.5KW(25HP) |

| Milling head speed | 0-590 |

| Milling head spindle taper | NT50 |

| Cutting diameter | 200mm |

| Milling head display | High precision digital caliper |

Power drive standard

Dongguan Portable Tools Co.,Ltd provide the on site gantry milling machine. The linear milling machine gets different electrical power for different country. 2 phase or 3 phase, 110V/220V/380V/415V. It meets your country standard. The power drive could be electric motor / pneumatic motor and servo motor / hydraulic power pack system.

X/Y/Z drive model

In situ linear milling machine has 3 different feed. X and Y axis are electric drive model. Z axis spindle head is manual handle , the power comes as hydraulic power as usually. Hydraulic power pack has strong torque and stability, but heavy to move.

Spindle working ability

The spindle is able to handle cutting a diameter with 120-250mm. And single cutting depth for 10mm at most. Z spindle has different models to choose, they are NT30, NT40 , NT50. Different spindle comes with different cutting diameter. NT30 spindle match cutter head diameter for 120mm most. NT40 spindle match cutter head diameter for 160mm most. NT50 spindle match cutter head diameter for 250mm most.

Multifunctional working condition

The spindle head adaptor plate that it can be used for horizontal milling and even working Vertically. Drilling function is also available to achieve.

Transportation

The standard transportation of gantry milling machine is wooden box package. If you need a steel pallet with forklift box section feet of 250 to 300 square to enable forklift access to load and offload, that’s also ok to manufacture.

We could manufacture a steel frame welded to the steel pallet with the milling unit in a 2mm galvanised box with padded wooden inside to accommodate the milling unit and all components

A second steel frame with a 2mm galvanised box to accommodate the power driven hydraulic unit also welded to the same steel pallet.

A 40mm mild steel frame milled flat on one side , bolt mounted to the bottom of the mill bed that protruded out 30mm from each side of the cast frame bed on all sides.

X,Y & Z have bed locks while machining to stop any side movement

The lifting lugs welded to the pallet, milling machine base plate and hydraulic power pack as we need to lift this all ± 20 meters up to the job.

Hydraulic pressure hoses will need to be as least 10mt long for the X,Y and Z motors.