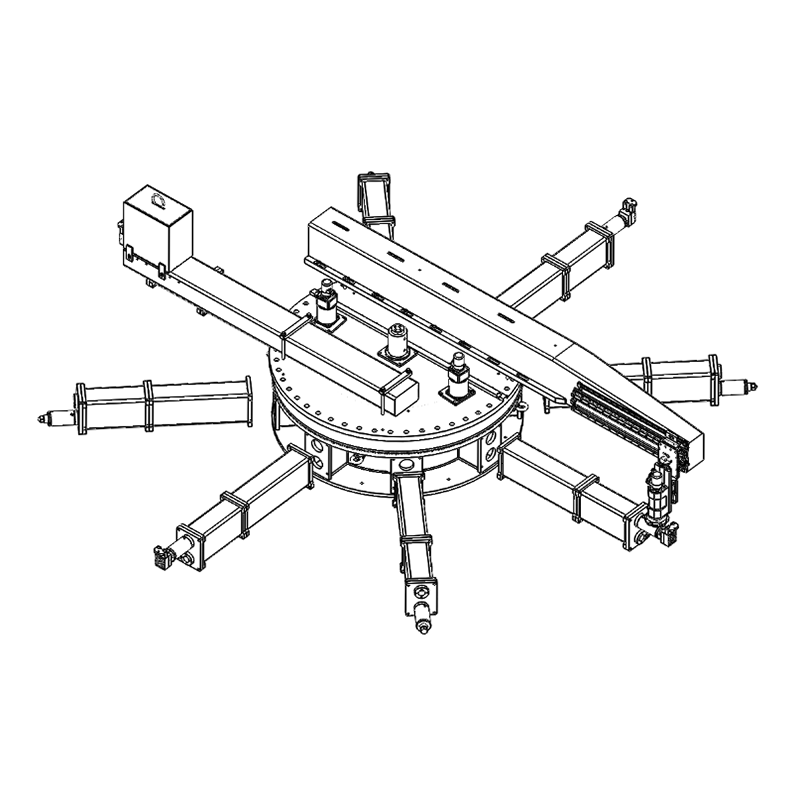

Good Quality Orbital Milling Machines - OMM3000 Orbital Milling Machine – Portable Tools

Good Quality Orbital Milling Machines - OMM3000 Orbital Milling Machine – Portable Tools Detail:

Detail

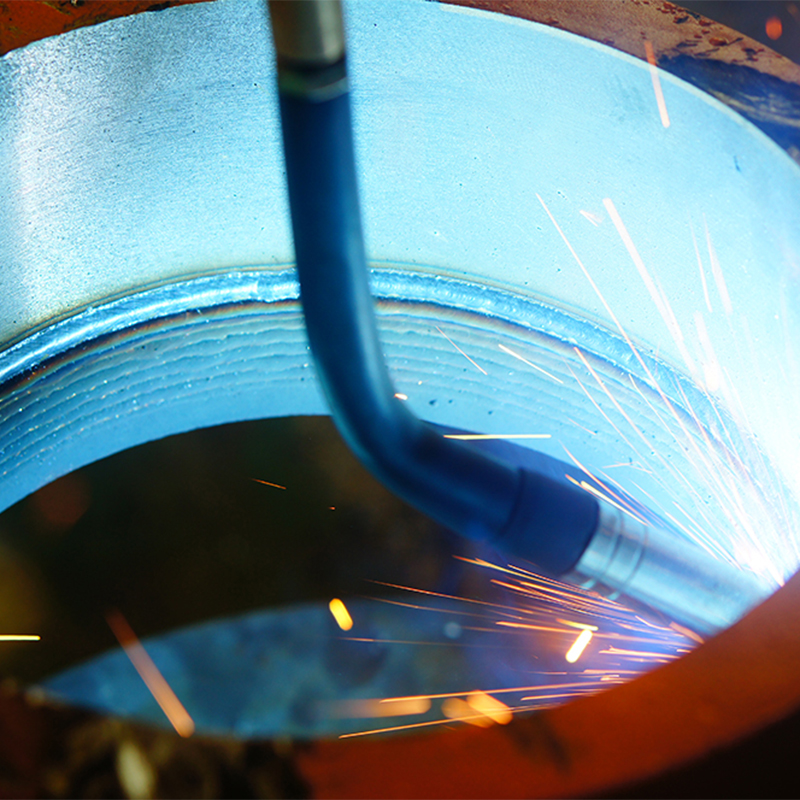

Suitable for on-site turning of base flanges made of steel, copper and stainless steel.

Mainly used for processing planes, inner holes, bosses, sealing grooves, etc.

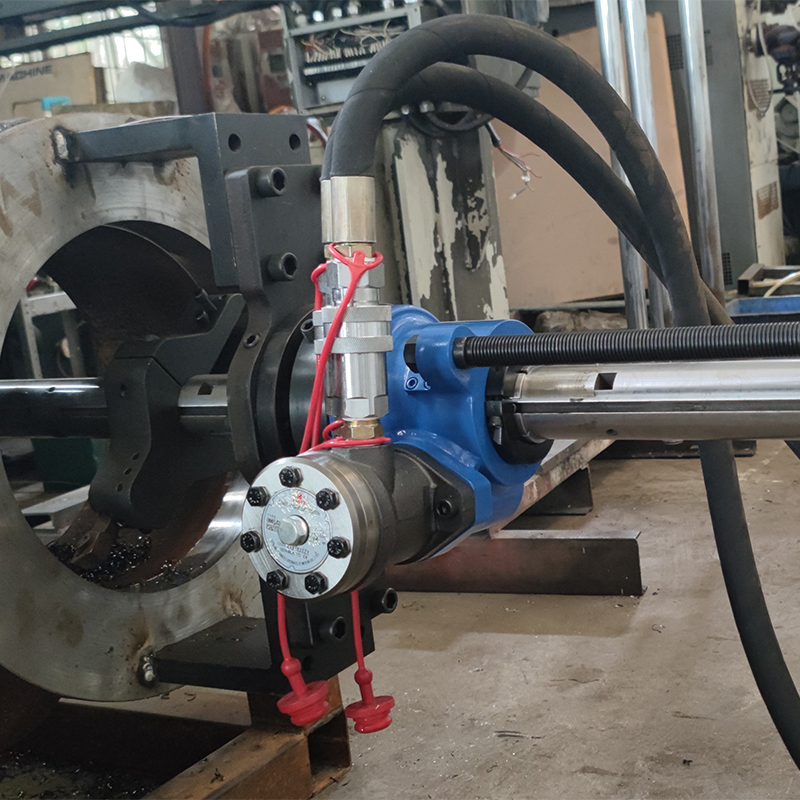

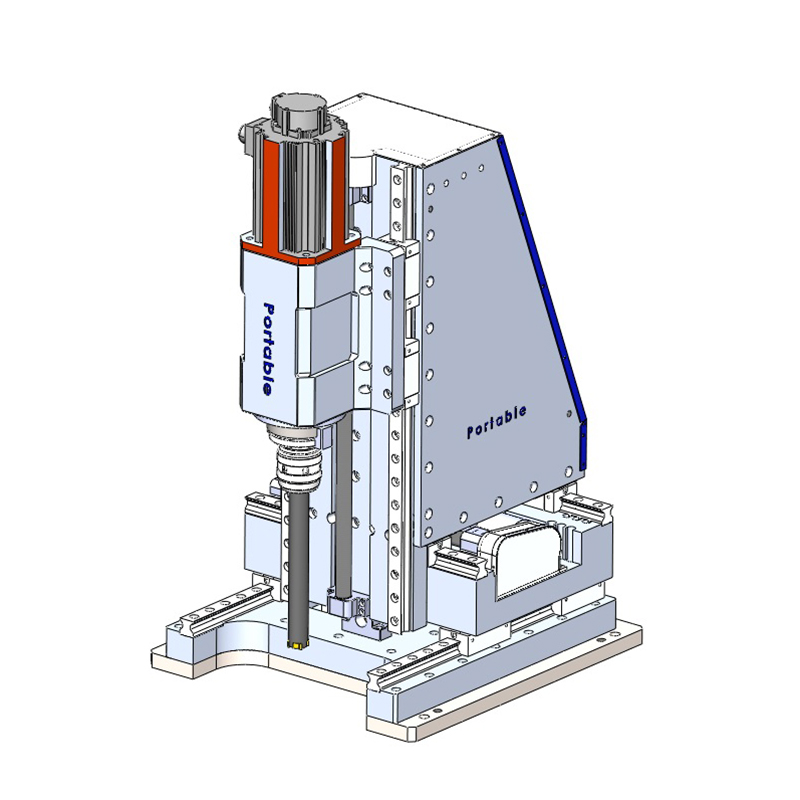

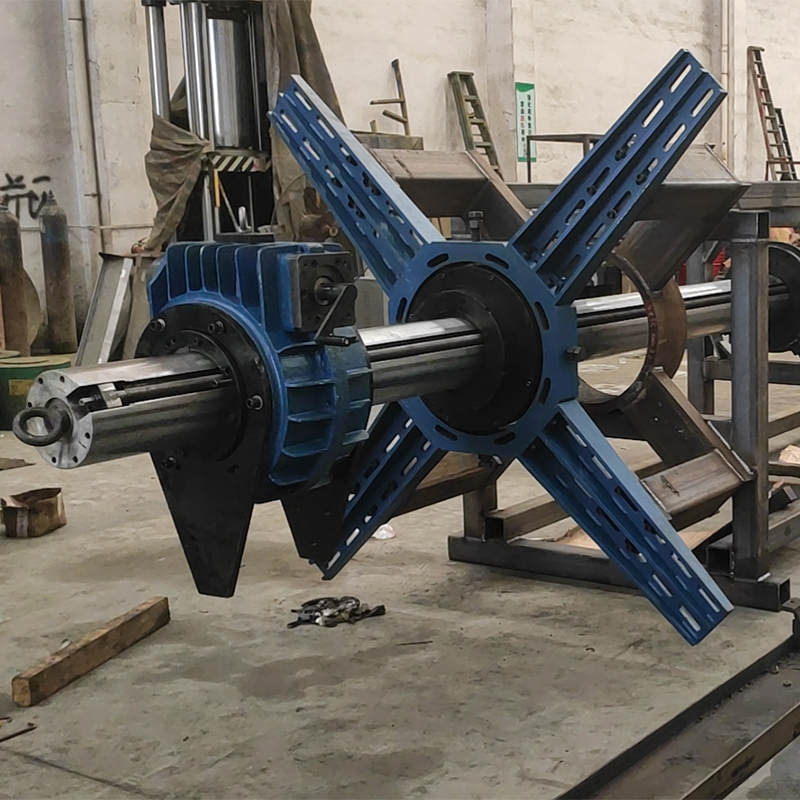

The modular design is adopted, which can be installed horizontally, vertically or reversely according to the working conditions on site.

Heavy-duty backlash-free bearings are used to ensure that the body runs smoothly and without vibration.

Adopt high-precision, reliable actuators, with good stability, durability and dynamic response.

It is installed and fixed with an 8-jaw inner diameter chuck, which is convenient and quick to install and adjust.

It has the characteristics of high rigidity, high precision and compact structure.

It has the characteristics of high horsepower and step less speed regulation of constant torque between various speeds.

The cutting force is large, and the cutting depth can reach 5mm during rough machining.

High machining accuracy, surface roughness can reach Ra1.6 during finishing

Benefits

High torque drive with a low 60 dB noise level

• Latest linear technology for durability and repeatable accuracy

• Wide range of portable, precision tooling of small and large scale deployed at stations around the globe

• Specialized laser guided measuring/alignment equipment

APPLICATIONS

- Typical applications:

- • Piping system flanges

- • Valve flanges and bonnet flanges

- • Heat exchanger flanges

- • Vessel flanges

- • Flange faces on piping systems

- • Pump housing flanges

- • Weld preps

- • Tube sheet bundles.

- • Bearing mounting bases

- • Final drive hubs

- • Bull gear faces

- • Manufacturing of mining equipment

- • Slew rings

- • Bearing mounting bases

- • Crane pedestal flange.

Problems Most Often Observed/Addressed

- Leaking Mating Surfaces

- Out Of Line Mating Surfaces

- Worn out / Damaged Landing Surfaces

- Corroded Guide Rails / Foundations

- Seized/sheared bolts

- Cracked/broken metal components

Product detail pictures:

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for Good Quality Orbital Milling Machines - OMM3000 Orbital Milling Machine – Portable Tools , The product will supply to all over the world, such as: Jordan, Paris, Tajikistan, Products have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the products performance and safety to meet the markets and strive to be nice A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very to support your business in China.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a excellent partner!