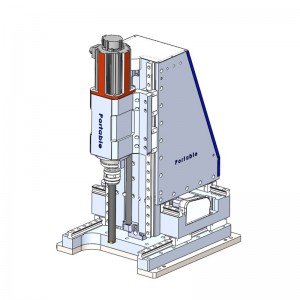

LMB300 Linear Milling Machine

Detail

LMB300 linear milling machine, a 3 axis portable on site line milling machine,provide the in situ service for on site jobs, which deliver the same precision tolerance with the workshop. These on site linear milling machine could be mounted and fixed onto the workpiece with different options, including Permanent magnet or bolting, chain clamps and sacrificial plates...

LMB300 portable line milling machine could be moved on X axis, Y axis and Z axis. X stroke for 300mm, Y stroke for 100-150mm, Z stroke for 100 or 70mm. The body size could be customized according to your requirement. The milling spindle head taper with R8. The power unit with 2400W or 1200W electric motor for the drive unit. This is a manual milling machine, it’s used for limited room and space with portable weight for on site milling jobs. Including the weld bead shaving on a wall or on a floor.

On site milling machine is designed to carry out a wide range of in-situ milling applications, it’s incredibly versatile, including heat exchangers, pump and motor pads, steel mill stands, ship building, turbine split lines.

This onsite line milling machine offers good flexibility for the operators that have different milling needs for the on site service.

Unique bed length section design provides superior rigidity and flexibility. The permanent magnet base could be mounted on any steel plate fast and easy. It’s easy to operate the milling machine with the handle by one single operator nice and easy. It turns several works’ job into one single person’.

Precision ball screws in X,Y and Z axis assemblies allow precise location of milling head do the movement more precision.

Reduced friction rail system allows extremely smooth, continuous, and non stick-slip travel.

Precisely machined and aligned rails with advanced lubrication make machining applications smooth and efficient.

Low friction system reduces maintenance costs and extends product life.

Machining capabilities include milling, drilling with different equipment.

The portable 3 axis manual line milling machine could be mounted anywhere and customized with different stroke with your requirement.