Frequently Asked Questions About On site Gantry Milling Machine

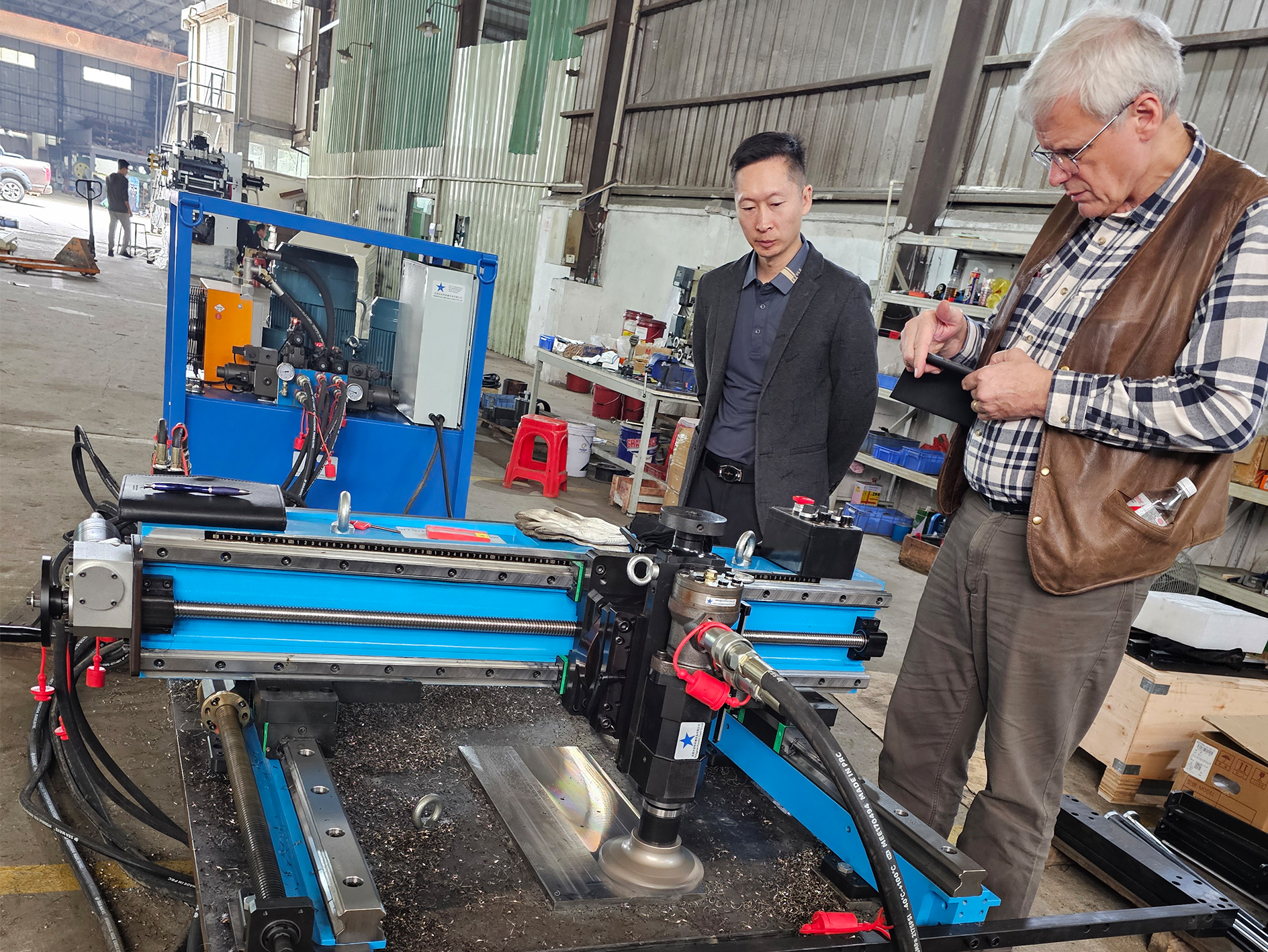

Dongguan portable tools co.,ltd as a professional factory of on site machine tools, we design and manufacture different kind of on site milling machines,including gantry milling machine, linear milling machine and other customized line milling machine as request.

Gantry milling machine, we call it bridge moving milling machine or bridge type gantry milling machine.

Gantry milling machine, also known as gantry milling machine, is a milling machine with a gantry frame and a long horizontal bed. Multiple milling cutters can be used to process surfaces at the same time on a gantry milling machine. The processing accuracy and production efficiency are relatively high. It is suitable for processing the plane and inclined surfaces of large workpieces in batch and mass production. CNC gantry milling machines can also process spatial curved surfaces and some special parts.

The appearance of the gantry milling machine is similar to that of the gantry planer. The difference is that its crossbeam and column are not equipped with a planer tool holder but a milling cutter holder with a spindle box, and the reciprocating motion of the longitudinal worktable of the gantry milling machine is not the main motion, but the feed motion, while the rotational motion of the milling cutter is the main motion.

The gantry milling machine consists of a gantry frame, a bed worktable and an electrical control system.

The gantry frame consists of columns and a top beam, with a crossbeam in the middle. The crossbeam can be raised and lowered along the two column guide rails. There is a milling head with a vertical spindle on the crossbeam, which can move horizontally along the crossbeam guide rails. A milling head with a horizontal spindle can also be installed on each of the two columns, which can be raised and lowered along the column guide rails. These milling heads can process several surfaces at the same time. Each milling head has a separate motor, speed change mechanism, operating mechanism and spindle components, etc.

Why do we need the on site gantry milling machine?

On-site processing machine tools are machine tools that are installed on parts to process parts. They are also called on-site processing equipment. Because early on-site processing machine tools were relatively small, they were called portable machine tools; because they are mobile, they are also called mobile machine tools.

Many large parts cannot be installed on ordinary machine tools for processing due to their large size, heavy weight, difficulty in transportation or difficulty in disassembly, and the machine needs to be installed on the parts to process these parts.

Such as on-site processing lathes, on-site processing milling machines, on-site processing drilling machines, on-site processing boring machines, on-site processing turning and boring machines, on-site processing boring and welding machines, on-site processing grinders, beveling machines, chamfering machines, valve grinders, etc.

We manufacture the on site milling machine to replace the machining in shop, it saves the cost and energy for the on site service machining.

What’s is the advantage of on site machine tools, especially the gantry milling machine?

High efficiency and speed: On-site processing machines can achieve efficient and fast production, greatly improving production efficiency.

High precision: The products manufactured by processing machines are of high precision, reliable quality, and good stability, which can ensure product quality and performance.

Mobility: On-site processing machines are usually mobile, called portable machine tools or mobile machine tools, which are suitable for processing large parts.

High degree of automation: Modern processing machines use highly integrated automated control systems, which reduces manual intervention and improves production efficiency.

How do we know what kind of gantry milling machine we need?

Gantry milling machine as a on site linear milling machine, we will suggest you the suitable size as long as you can provide the space requirements and power you have on site.

What kind of power do we choose and if we can order the extension of X axis in the future if we have bigger size to use?

We will suggest you the Hydraulic power unit as the power for the gantry milling machine normally. As we know, the gantry milling machine has 3 axis for movement, so it will has 3 units of power.

Electric motor, servo motor and hydraulic power are all right for them.

As X and Y axis, we recommend electric motor if the budget is limited. Because electric motor is more economical and easy to get connected for the electricity of 380V.

If you have limited space and need powerful torque, the servo motor will be the good choice. Servo motor has little body, but it gets the high torque with the planetary gear reducer. It will enhance sever times of torque when machining. And we use Panasonic servo motor (made in Japan)for rotation of Z axis, it’s more reliable and stronger than most of brand.

Hydraulic power unit gets the most powerful for the gantry milling machine, but also has the most biggest size compare to electric motor and servo motor.

We packed the machines with firm wooden packages as well to keep the transportation safe and well to destination.