Before we discuss about why use on site line boring machine tools, we need to know what the line boring machine is.

What is the in line boring machine?

Portable line boring machine is a portable light tools to bore or repair the hole and blind holes , so the accuracy will comes back to the ideal situation .

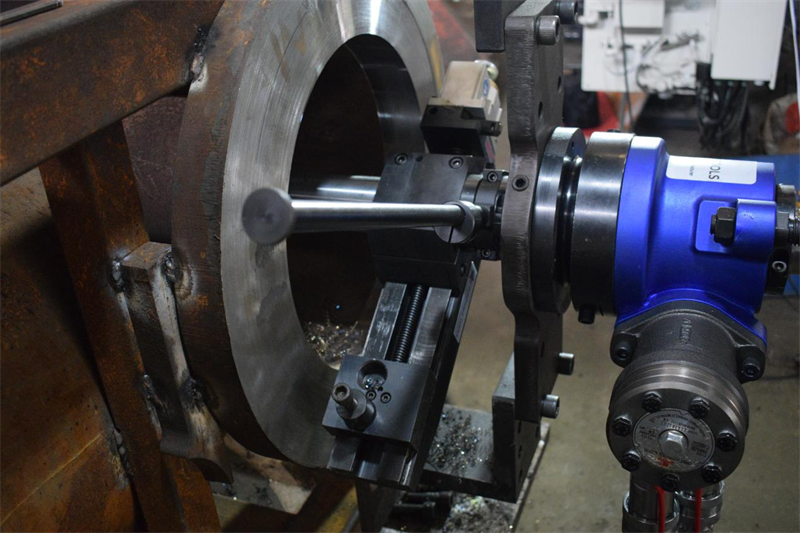

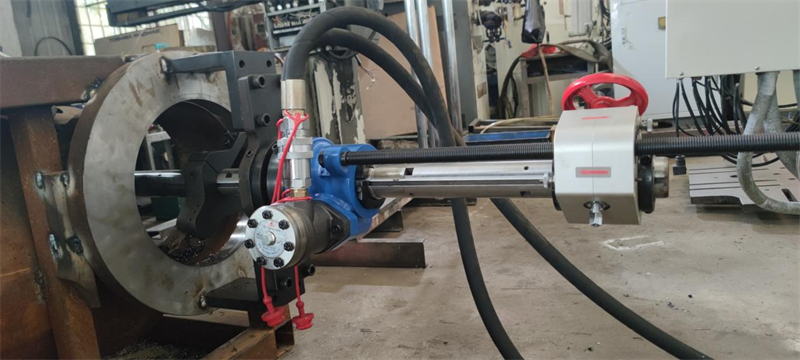

Compare with the heavy line boring machine in the workshop. In line boring machine is designed and fabricated to bore clean and accurate holes in field. It can’t work with the heavy duty machines or move easily in short time, or it will cost more.

Portable line boring machines do the parallel bores, they can cut tapered holes or machine the surface of workpiece with a facing head.

For the accuracy of on site line boring machine, it has difference with the machines in the shop. But with some line boring machines, the margin of error is less than 0.002%.

What is the line boring machine boring diameter?

Line boring machine could be customized as your requirement. Different models works with different working range. Our line boring diameter range: 35-1800mm.

Each line boring machine gets it’s owns design. Some models for the impact room, so the parts are pretty compact and reliable.

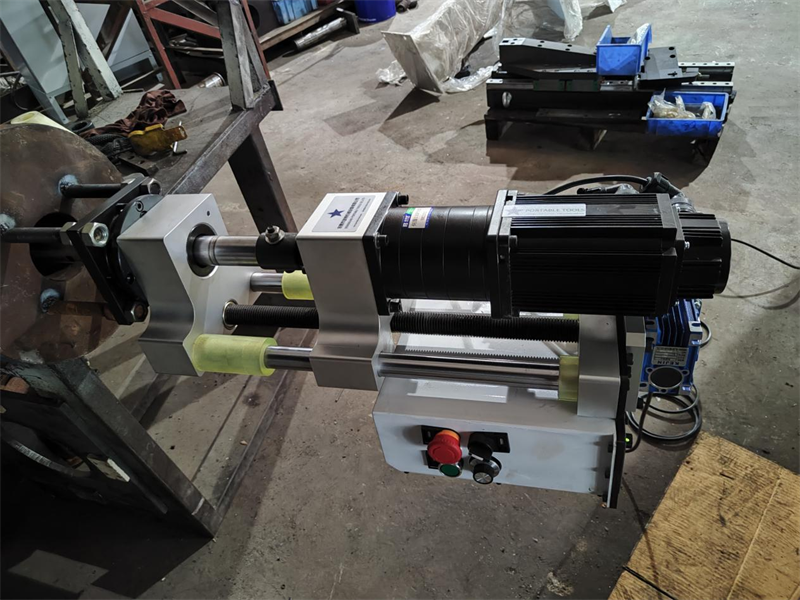

Such as the Portable line boring machine LBM40, the main body designed on one side, it gets the servo motor-1.2KW as the power, also the worm gear to match the motor, it enhance the torque several time.

And the control box on the machine, which makes it more convenient to carry out, save more time in filed.

A portable line boring machine could match different power. Electric motor, servo motor, pneumatic motor or hydraulic power unit. Different power with it’s own advantage for in situ service.

Portable line boring machine with electric motor:

For this model: LBM50 Line boring machine, it bore holes from 38-300mm. Not a pretty big range hole for it, a electric motor with 1.2kw is enough to work well.

Electric motor has no worm gear, it’s 5kg only. It’s a ultra-portable line boring machines.

LBM60 with hydraulic power unit(18.5kw or 11kw). Hydraulic power pack gets it’s advantage for the torque, but short of heavy duty of it’s body. It weights about 450kg without oil.

What kind of power you choose is flexible, it changes according to the situation of in field.

If the oil or gas industries requires no spark, the electric motor and servo motor are failed. Then the hydraulic power unit with pretty longer tube will work or the pneumatic motor. The hydraulic power units need voltage for 380V or 415V, so it works. The pneumatic motor needs big capacity of compressor and Coarser tube than the machine itself.

Application of line boring machine

As introduced, portable line boring machine could be used on many kind of business, no matter the shipyard build, the power station, or the oil &gas, infrastructure, there are so many industries or workpieces which needs the on site machining and service.

Application as:

Bridges

Manufacturing

Mining

Petrochemical

Rail

Gearbox parts and housings

Various applications in shipbuilding, including rudder parts and stern tubes

Driveshaft housing

A-frame supports

Hinge pins

Turbine casing

Engine Bedplates

Cylinder Liner locations

Clevis plate bores

It’s not all of list, only the sample. There are so many machinery or other place need portable line boring machine to ensure the workpiece to be machined up to their needed accuracy and precise.

How to choose the suitable portable line boring machine?

You could share your situation on site with our company, we will provide the suggestion after evaluating with our engineer.

Normally we will need to know the details of the workpieces, such as the boring diameter, the length of the holes, depth of each hole, pictures of workpieces. With CAD or other drawing of details are both helpful.

If you have engineer to evaluate, that’s better. That will save both energy to short the unnecessary process.

Our factory accept customized machines as your requirement, welcome to contact us.